#1

Unveiling of the symbol by Amina Mohammed, deputy secretary-general of the United Nations, and Liselott Andersson, ambassador of Sweden to the UAE, at UN Day on 24 October.

#2

Shaping the handles of the gun require knowledge of wood behavior and a great piece of experiance.

#3

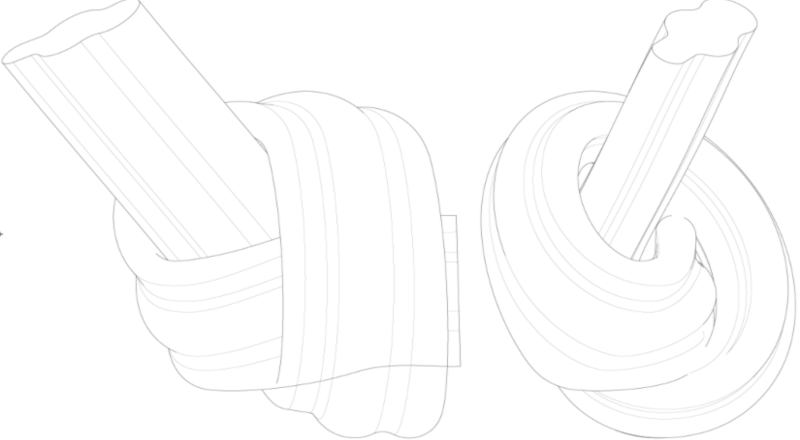

A big chunk of wood, carefully glued, with the knots outside the shape of the future knot.

#4

The first cut of the knot was really nervous.

#5

Shaping the knot or chainsaw massacre? A lot of thoughts behind every cut.

#6

2d drawings from a 3d model is sometimes helpful. But can really mess up your mind.

#7

3D scanning the surface of a small model of the gun, Is a start to make a bigger model.

#8

Fine shaping or pure magic. Slowly the knot is revealing behind all the wood. It's in there somewhere.

#9

Finally the rough shaping have made it posible to start imagine the lines and curvature of the knot.

#10

Cutting the internal shape is tricky, all the wood fibers are directed into the wood.

#11

Checkering of the handle require a lot of patience an a steady hand.

#12

To make the trigger gard, several thin layers of wood are heated, bent and glued together in a light and strong shape.

#13

Piece by piece the gun is ready for assembly.

#14

Almost ready, small adjustments and final sanding before a thin layer of varnish.

#15

Two tired and really proud carpenters finally see the result of three months of intence work.